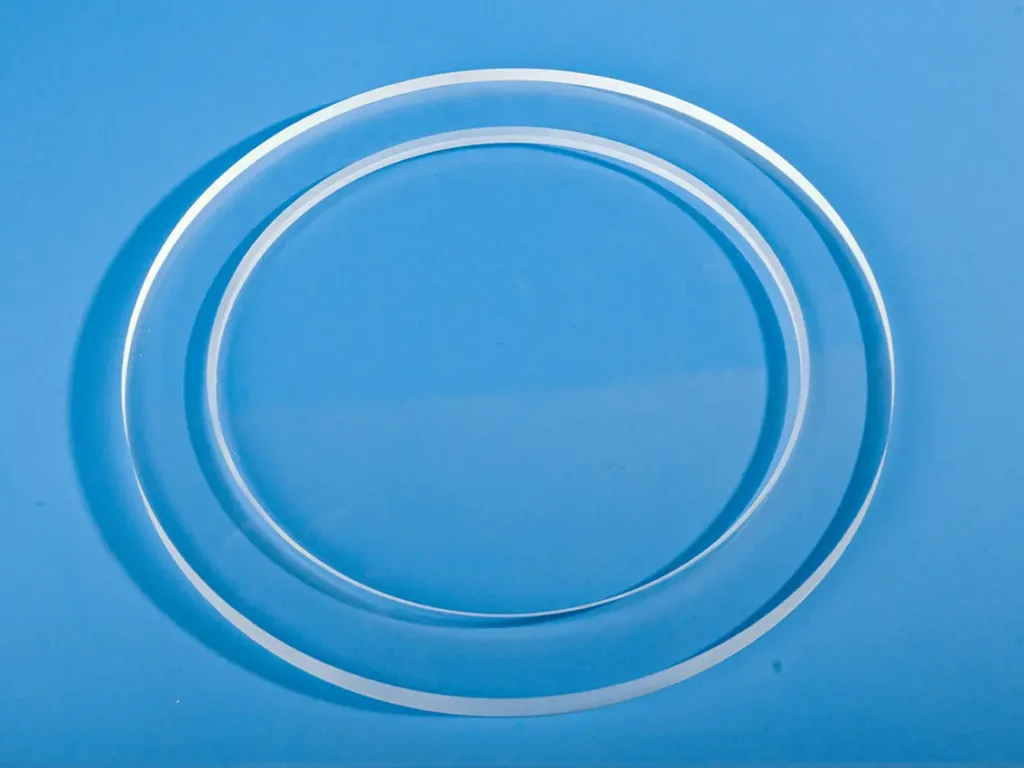

Precision Quartz Plates, Discs & Substrates

Aoxin Quartz is a leading manufacturer of high-quality quartz plates, discs, windows, and substrates. We offer fused quartz and fused silica materials known for their exceptional purity, thermal resistance, and optical clarity across a wide spectrum (UV, Visible, IR). Our precision manufacturing capabilities ensure excellent flatness, parallelism, and surface quality, making our products ideal for optics, semiconductor, industrial, and scientific applications. Both standard and custom sizes/shapes are available.

Excellent Optical Transmission

High transparency from deep UV through IR spectrum (grade dependent)

Superior Surface Quality

Available with high-quality polishing for optical applications (low scatter, high flatness)

High Purity Levels

Ensures minimal contamination in sensitive processes

Outstanding Thermal Properties

Low thermal expansion, excellent thermal shock resistance, high-temperature stability

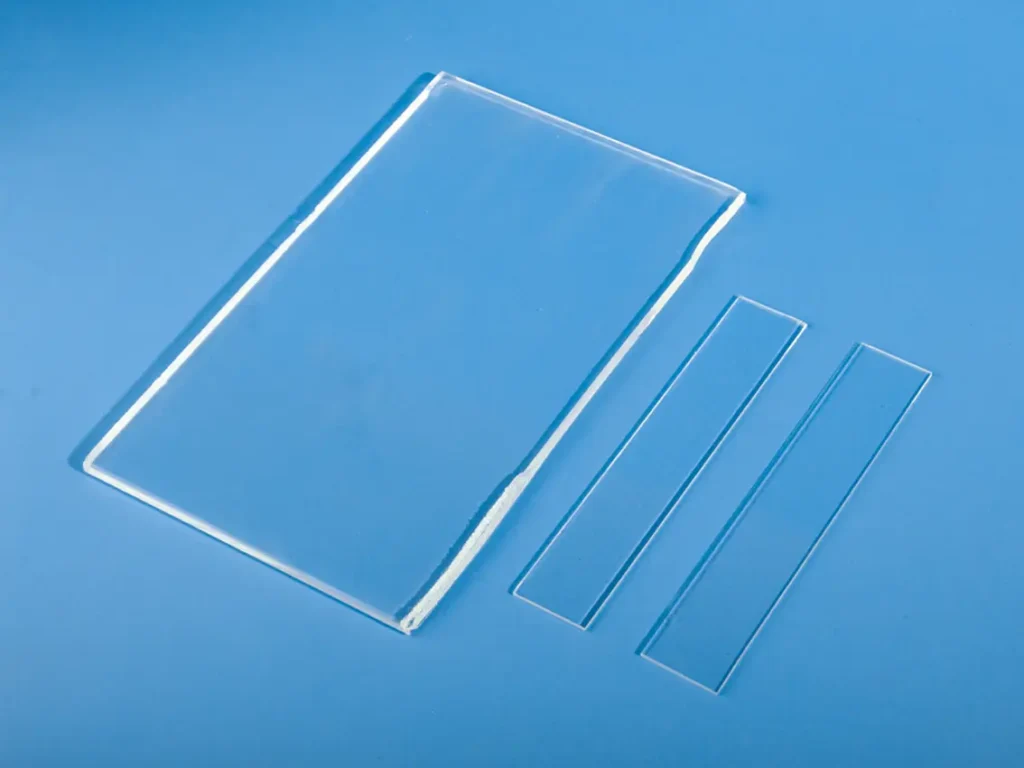

Our Quartz Glass Products

We manufacture a wide range of quartz glass products available in various grades and dimensions, or fully customized to your specifications.

Comparing Quartz Glass Sheets by Manufacturing Methods

Rough Cast Quartz Plates

Wide thickness tolerance;Surface with slight striations;Light transmittance: 70-80%;Outer dimension tolerance: ±0.01 to ±0.1 mm.

Frosted Quartz Sheets

Thickness tolerance: ±0.01 to ±0.1 mm;Outer dimension tolerance: ±0.01 to ±0.1 mm;Surface Roughness: Fine Grind / Coarse Grind.

Cold Polished Quartz Plates

Thickness tolerance varies with size: ±0.01 to ±0.5 mm;Outer dimension tolerance: 0.01 mm;Light transmittance: ≥94%.

Processing Methods for Achieving Transparency in Quartz Sheets

Cold Polishing after Precision Machining

Outer dimension tolerance: ±0.01 mm

Light transmittance after cold polishing: ≥94% (High Transmittance)

Fire Polishing after Precision Machining

Outer dimension tolerance: ±0.01 mm, dependent on polishing intensity and initial roughness; surface exhibits a granular texture/finish.

Common Applications

Our quartz plates and discs serve critical functions in diverse fields

Semiconductor Manufacturing

Process chamber windows, Masks, Substrates, Wafer carriers (parts)

Industrial Processes

Sight glasses, Furnace windows, Heat shields, Chemical resistant linings.

Optics & Photonics

Windows, Lenses (blanks), Filters, Substrates, Mirrors (blanks), Beam Splitters, Debris Shields

Lighting

UV lamp covers, Protective windows

Scientific Research

Viewports, Sample holders, Specialized optical components

Medical & Biotechnology

Slides, Cuvettes (components), Microfluidic device components.

AoXIN QUARTZ

Custom Quartz Plate & Disc Solutions

Aoxin Quartz specializes in manufacturing custom quartz plates, discs, and substrates tailored to your unique requirements. We can accommodate custom shapes, precise dimensions, tight tolerances (including flatness, parallelism, and surface finish), specific edge profiles, drill holes, slots, and apply coatings . Provide us with your drawings or specifications, and our engineering team will work with you to produce the ideal component.

Related Services

We offer a range of fabrication services to complement our quartz plates and discs: Precision Cutting & Dicing, Grinding & Lapping, Polishing (Commercial & Optical), Drilling & Machining, Coating Services , Edge Finishing.

Frequently Asked Questions

Find answers to commonly asked questions about our products and services.

Are you a direct manufacturer or a distributor of quartz glass?

Aoxin Quartz is a direct manufacturer of quartz glass products. We handle the entire process from raw material selection (or sourcing) to final fabrication and quality control at our own facility located in China.

What grades/purity levels of quartz glass do you offer?

We offer various grades to meet different application needs, including standard purity fused quartz, high-purity fused quartz (e.g., for semiconductor applications), synthetic fused silica (JGS1, JGS2, JGS3 equivalents), and opaque quartz. Please specify your application or required purity level (e.g., SiO2 content > 99.99%) when requesting a quote.

Do you accept custom orders based on drawings? What is the process?

Yes, custom fabrication is a core part of our business. The typical process is:

1. You provide detailed drawings (e.g., CAD files like DWG, STEP) and specifications (material grade, tolerances, quantity).

2. Our engineering team reviews the feasibility and provides technical feedback if necessary.

3. We provide a formal quotation including price and estimated lead time.

4. Upon order confirmation, we proceed with manufacturing according to the approved drawings.

5. Quality inspection is performed before shipment.

Please send your drawings to [email protected] or use our quote request form.

What is your Minimum Order Quantity (MOQ)?

Our MOQ varies depending on the product type and complexity. For standard items like tubes or rods, we might have lower MOQs compared to highly customized precision components. Please contact our sales team with your specific requirements for details.

What is the typical lead time for custom and standard products?

Lead times depend on product complexity, quantity, and current production schedules. Standard items might ship within 7 days. Custom orders typically range from 1 to 4 weeks after drawing approval. We will provide a specific estimated lead time with your quote.

Can you provide material certifications or Certificates of Conformance (CoC)?

Yes, we can provide material certifications detailing the properties (like purity) and Certificates of Conformance upon request, confirming that the products meet the specified requirements and standards.

How can I get a quote? What information is needed?

The best way is to use the “Request a Quote” form on our website or email us at [email protected]. Please provide as much detail as possible:

1. Product type (tube, plate, rod, custom part, etc.)

2. Material grade/purity requirement

3. Dimensions and tolerances (drawings are preferred for custom parts)

4. Quantity needed

5. Application (helps us understand the context)

6. Your contact information

Do you provide samples?

Samples for standard materials or simple items may be available, sometimes at a cost depending on the item. For custom components, prototyping might be part of the development process. Please discuss your sample needs with our sales team.

Contact Us

Address

No.39 Shixian West Road, Huifeng Township, Donghai County,Lianyungang,Jiangsu, China

Send Us a Message

Here\’s how you can contact us for any questions or concerns.