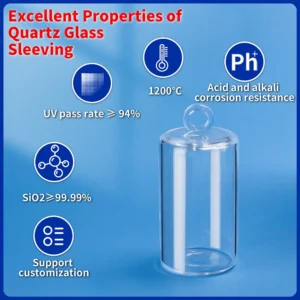

1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

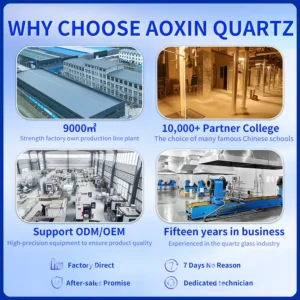

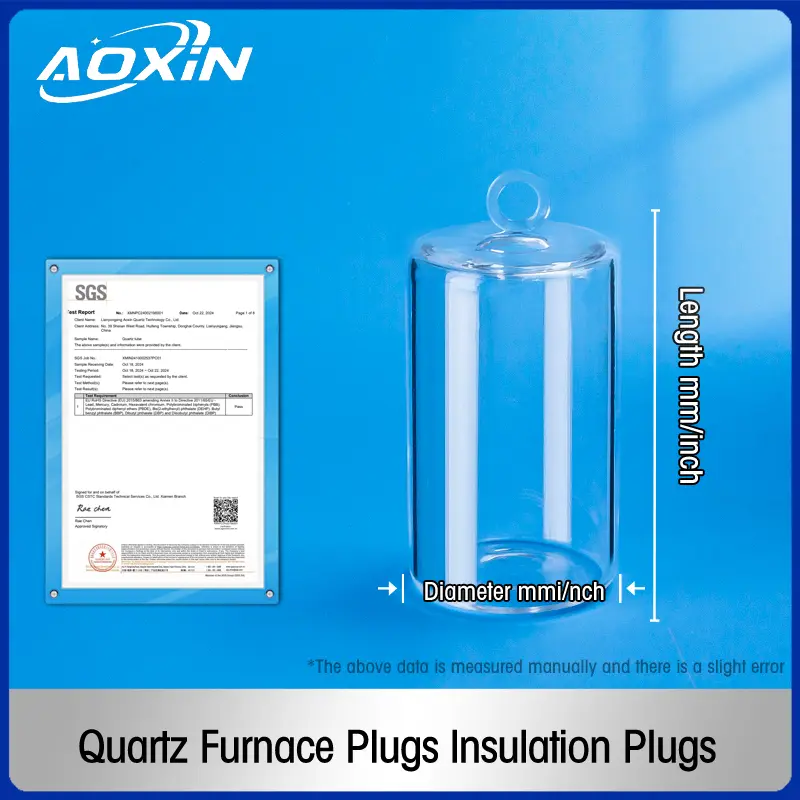

Aoxin Quartz manufactures high-quality Quartz Furnace Tube Plugs (also known as Quartz Furnace End Caps), essential components for sealing the ends of furnace tubes in high-temperature processes. Crafted from high-purity fused quartz (SiO2 > 99.99%), these plugs provide an excellent seal, maintaining atmosphere integrity and preventing heat loss. They are designed with a convenient handling loop, firmly welded for durability, and are available in both clear and frosted finishes to suit various operational needs. With exceptional resistance to temperatures up to 1200°C and aggressive chemical environments, our furnace tube plugs are built for reliability. Custom designs are fully supported to match your specific tube dimensions and application requirements.

- Product Name : Quartz Furnace Tube Plug / Quartz Furnace End Cap

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

| Diameter (mm) | Length (mm) | Applicable outer diameter (mm) | Diameter (in) | Length (in) | Applicable outer diameter (in) |

|

|---|---|---|---|---|---|---|

| 22 | 65 | 25 | 0.87 | 2.56 | 0.98 | |

| 18 | 65 | 25 | 0.71 | 2.56 | 0.98 | |

| 20 | 65 | 25 | 0.79 | 2.56 | 0.98 | |

| 28 | 65 | 40 | 1.10 | 2.56 | 1.57 | |

| 24 | 65 | 30 | 0.94 | 2.56 | 1.18 | |

| 25 | 65 | 30 | 0.98 | 2.56 | 1.18 | |

| 30 | 65 | 40 | 1.18 | 2.56 | 1.57 | |

| 32 | 65 | 40 | 1.26 | 2.56 | 1.57 | |

| 40 | 65 | 50 | 1.57 | 2.56 | 1.97 | |

| 35 | 65 | 50 | 1.38 | 2.56 | 1.97 | |

| 45 | 65 | 60 | 1.77 | 2.56 | 2.36 | |

| 34 | 65 | 50 | 1.34 | 2.56 | 1.97 | |

| 42 | 65 | 50 | 1.65 | 2.56 | 1.97 | |

| 38 | 65 | 50 | 1.50 | 2.56 | 1.97 | |

| 48 | 65 | 60 | 1.89 | 2.56 | 2.36 | |

| 52 | 65 | 60 | 2.05 | 2.56 | 2.36 | |

| 50 | 65 | 60 | 1.97 | 2.56 | 2.36 | |

| 58 | 65 | 70 | 2.28 | 2.56 | 2.76 | |

| 60 | 65 | 70 | 2.36 | 2.56 | 2.76 | |

| 65 | 65 | 80 | 2.56 | 2.56 | 3.15 | |

| 66 | 65 | 70 | 2.60 | 2.56 | 2.76 | |

| 70 | 65 | 80 | 2.76 | 2.56 | 3.15 | |

| 62 | 65 | 70 | 2.44 | 2.56 | 2.76 | |

| 68 | 65 | 80 | 2.68 | 2.56 | 3.15 | |

| 78 | 65 | 90 | 3.07 | 2.56 | 3.54 | |

| 80 | 65 | 90 | 3.15 | 2.56 | 3.54 | |

| 84 | 65 | 100 | 3.31 | 2.56 | 3.94 | |

| 85 | 65 | 100 | 3.35 | 2.56 | 3.94 | |

| 88 | 65 | 100 | 3.46 | 2.56 | 3.94 | |

| 90 | 65 | 100 | 3.54 | 2.56 | 3.94 | |

| 95 | 65 | 110 | 3.74 | 2.56 | 4.33 | |

| 98 | 65 | 110 | 3.86 | 2.56 | 4.33 | |

| 100 | 65 | 110 | 3.94 | 2.56 | 4.33 | |

| 105 | 65 | 120 | 4.13 | 2.56 | 4.72 | |

| 107 | 65 | 120 | 4.21 | 2.56 | 4.72 | |

| 110 | 65 | 120 | 4.33 | 2.56 | 4.72 | |

| 115 | 65 | 130 | 4.53 | 2.56 | 5.12 |

Features

- Effective Sealing: Designed to provide a tight seal for furnace tubes, critical for controlled atmospheres, minimizing contamination, and ensuring efficient heating.

- Superior Material Purity (SiO2 > 99.99%): Ensures chemical inertness, preventing reactions with process materials and maintaining sample purity.

- Extreme Temperature & Chemical Resistance: Reliably performs at temperatures up to 1200°C and withstands corrosive acids and alkalis common in furnace environments.

- Durable & Convenient Design: Features a robust, firmly welded handling loop for easy and safe insertion or removal. Available in clear (high UV transmittance >94%) or frosted finishes.

- Customization Expertise: We can manufacture plugs and end caps to your exact specifications, including diameter, length, and special features.

- Enhanced Process Integrity: Helps maintain stable furnace conditions, leading to more consistent and reproducible results.

- Certified Quality: Manufactured under stringent quality controls and backed by certifications (CE, ISO, RoHS, SGS), ensuring reliability and performance.