1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

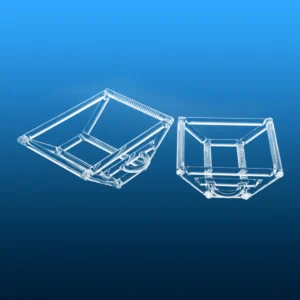

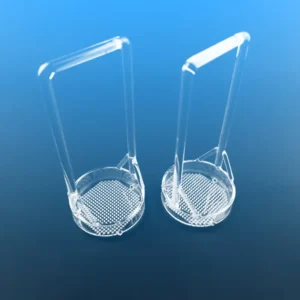

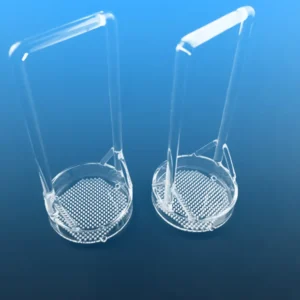

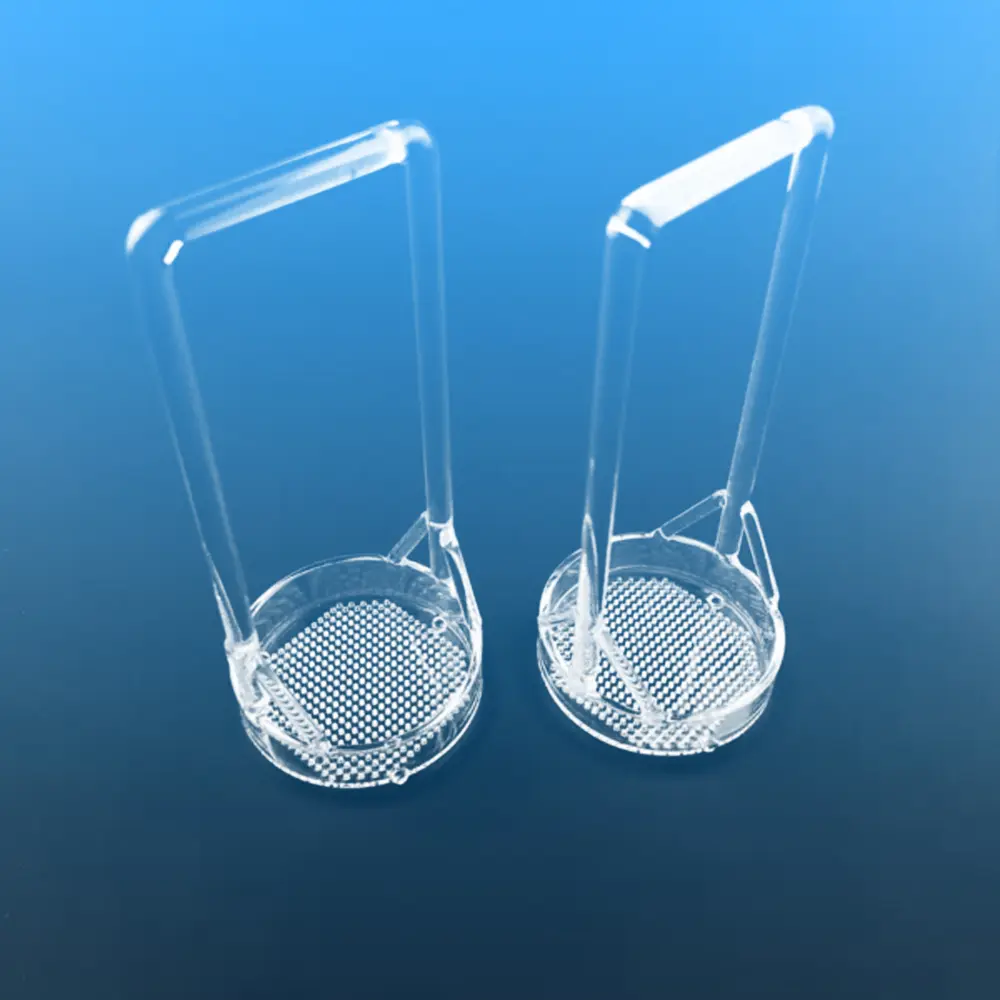

Aoxin Quartz manufactures high-quality Quartz Wafer Carriers featuring a perforated base and an integrated long handle, often referred to as Quartz Dipping Baskets. These carriers are meticulously designed for the manual handling and processing of semiconductor wafers or other flat substrates in wet chemical environments. Crafted from ultra-high purity fused quartz, the perforated base allows for rapid and complete drainage of process fluids, ensuring uniform treatment and efficient rinsing. The robust quartz handle provides safe and convenient immersion and retrieval from chemical baths, making these carriers ideal for cleaning, etching, and plating applications where material purity and chemical resistance are paramount.

- Product Name : Quartz Wafer Carrier with Perforated Base and Handle

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

Features

- Efficient Fluid Dynamics: The perforated base design ensures rapid drainage and free flow of processing liquids, promoting uniform chemical exposure and thorough rinsing of wafers.

- Ultra-High Purity: Fabricated from high-purity fused quartz to prevent any contamination of sensitive wafers or process chemistries.

- Superior Chemical Resistance: Inert to virtually all acids, solvents, and etching solutions commonly used in semiconductor and microfabrication processes.

- Safe Manual Handling: The long, sturdy quartz handle allows for safe immersion and retrieval of wafers from hazardous chemical baths, protecting operators.

- Thermal Stability: Suitable for use in heated chemical baths and can withstand thermal cycling associated with processing and drying.

- Durable Construction: Robust design and the inherent strength of quartz ensure a long service life even with frequent use in aggressive environments.

- Reduced Drag-Out: The perforated design minimizes the carry-over of process fluids between baths, improving process efficiency and reducing chemical consumption.

- Customizable: Available in various basket diameters, perforation patterns, and handle lengths to suit specific wafer sizes and operational needs.