1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

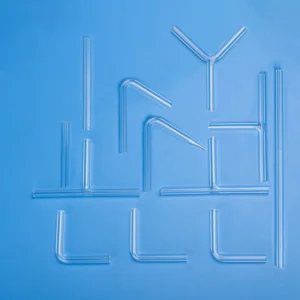

Aoxin Quartz manufactures this large, one-end-closed Quartz Tube (Model TQH200), specifically designed as a process chamber for VBF-1200X-H8 vertical bottom-loading furnaces. Measuring 8 inches in outer diameter and 13.4 inches in height, this robust chamber is crafted from high-purity fused quartz, enabling operation at temperatures up to 1200°C in atmosphere or 1100°C under vacuum. It features precisely located side ports (holes) near the open end, allowing for gas inlet/outlet, thermocouple insertion, or other process connections, making it ideal for various high-temperature material processing, annealing, and synthesis applications.

- Product Name : Large One-End-Closed Quartz Tube with Side Ports

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

| OD | 203mm ±0.5mm(8″) |

| ID | 192mm ±0.5mm(7.5″) |

| Tube Length | 340mm (13.39″) |

| Max. operating Temperature | 1100°C under vacuum 1200°C in atmorshpere |

Features

- Specific Compatibility: Designed as a direct fit for the VBF-1200X-H8 vertical furnace, ensuring seamless integration.

- High-Purity Quartz Construction: Provides an inert environment, minimizing contamination during high-temperature processing and ensuring sample integrity.

- Exceptional Thermal Performance: Safely operates at up to 1200°C in atmosphere and 1100°C under vacuum, with excellent thermal shock resistance.

- Functional Side Ports: Allows for controlled atmosphere, gas purging, vacuum application, or in-situ temperature monitoring via thermocouples.

- Large Processing Volume: The 8″ OD and 13.4″ height provide ample space for various sample sizes and batch processing.

- Durable & Robust: Thick-walled construction (based on OD/ID difference) ensures good mechanical strength at high temperatures.

- Optical Clarity (Typical for Quartz): Allows for visual observation of the process if the furnace design permits.

- Versatile Applications: Suitable for annealing, sintering, crystal growth, material synthesis, degassing, and other thermal treatments in a controlled environment.