1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

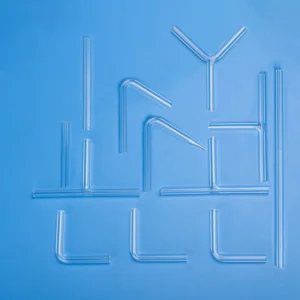

Complete Specifications

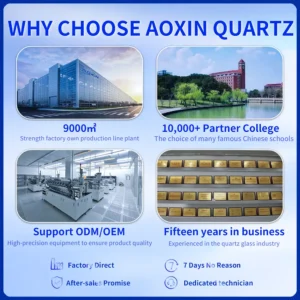

Aoxin Quartz specializes in the design and manufacturing of high-quality Quartz Glass Containers, tailored to a multitude of industrial and laboratory applications. From standard ‘Quartz Square Cylinders’ (rectangular boxes) and robust ‘Quartz Cleaning Tanks’ to fully customized fabrications based on your drawings, we leverage the exceptional properties of fused quartz. These containers offer outstanding resistance to high temperatures and chemical corrosion. Whether you require simple storage solutions or complex, integrated process vessels with features like lids, handles, partitions, or CNC-milled details, Aoxin Quartz is your expert partner with 15 years of dedicated experience.

- Product Name : quartz glass container

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

| Length (mm) | width (mm) | Height (mm) | Length (in) | width (in) | Height (in) |

|

|---|---|---|---|---|---|---|

| 10mm | 10mm | 10mm | 0.39″ | 0.39″ | 0.39″ | |

| 15mm | 15mm | 15mm | 0.59″ | 0.59″ | 0.59″ | |

| 20mm | 20mm | 20mm | 0.79″ | 0.79″ | 0.79″ | |

| 30mm | 30mm | 30mm | 1.18″ | 1.18″ | 1.18″ | |

| 40mm | 40mm | 40mm | 1.57″ | 1.57″ | 1.57″ | |

| 50mm | 10mm | 10mm | 1.97″ | 0.39″ | 0.39″ | |

| 50mm | 15mm | 10mm | 1.97″ | 0.59″ | 0.39″ | |

| 50mm | 15mm | 15mm | 1.97″ | 0.59″ | 0.59″ | |

| 50mm | 20mm | 15mm | 1.97″ | 0.79″ | 0.59″ | |

| 50mm | 30mm | 20mm | 1.97″ | 1.18″ | 0.79″ | |

| 50mm | 40mm | 25mm | 1.97″ | 1.57″ | 0.98″ | |

| 50mm | 50mm | 30mm | 1.97″ | 1.97″ | 1.18″ | |

| 50mm | 50mm | 50mm | 1.97″ | 1.97″ | 1.97″ | |

| 50mm | 50mm | 100mm | 1.97″ | 1.97″ | 3.94″ | |

| 60mm | 60mm | 60mm | 2.36″ | 2.36″ | 2.36″ | |

| 70mm | 70mm | 70mm | 2.76″ | 2.76″ | 2.76″ | |

| 80mm | 80mm | 80mm | 3.15″ | 3.15″ | 3.15″ | |

| 90mm | 90mm | 90mm | 3.54″ | 3.54″ | 3.54″ | |

| 100mm | 10mm | 10mm | 3.94″ | 0.39″ | 0.39″ | |

| 100mm | 15mm | 10mm | 3.94″ | 0.59″ | 0.39″ | |

| 100mm | 20mm | 15mm | 3.94″ | 0.79″ | 0.59″ | |

| 100mm | 30mm | 20mm | 3.94″ | 1.18″ | 0.79″ | |

| 100mm | 40mm | 25mm | 3.94″ | 1.57″ | 0.98″ | |

| 100mm | 50mm | 30mm | 3.94″ | 1.97″ | 1.18″ | |

| 100mm | 100mm | 30mm | 3.94″ | 3.94″ | 1.18″ | |

| 100mm | 100mm | 50mm | 3.94″ | 3.94″ | 1.97″ | |

| 100mm | 100mm | 100mm | 3.94″ | 3.94″ | 3.94″ | |

| 110mm | 110mm | 110mm | 4.33″ | 4.33″ | 4.33″ | |

| 120mm | 120mm | 50mm | 4.72″ | 4.72″ | 1.97″ | |

| 120mm | 120mm | 120mm | 4.72″ | 4.72″ | 4.72″ | |

| 130mm | 130mm | 130mm | 5.12″ | 5.12″ | 5.12″ | |

| 140mm | 140mm | 140mm | 5.51″ | 5.51″ | 5.51″ | |

| 150mm | 150mm | 150mm | 5.91″ | 5.91″ | 5.91″ | |

| 160mm | 160mm | 160mm | 6.30″ | 6.30″ | 6.30″ | |

| 170mm | 170mm | 170mm | 6.69″ | 6.69″ | 6.69″ | |

| 180mm | 180mm | 180mm | 7.09″ | 7.09″ | 7.09″ | |

| 190mm | 190mm | 190mm | 7.48″ | 7.48″ | 7.48″ | |

| 200mm | 200mm | 200mm | 7.87″ | 7.87″ | 7.87″ | |

| 200mm | 100mm | 30mm | 7.87″ | 3.94″ | 1.18″ | |

| 200mm | 100mm | 50mm | 7.87″ | 3.94″ | 1.97″ | |

| 210mm | 210mm | 210mm | 8.27″ | 8.27″ | 8.27″ | |

| 220mm | 220mm | 220mm | 8.66″ | 8.66″ | 8.66″ | |

| 200mm | 300mm | 200mm | 7.87″ | 11.81″ | 7.87″ | |

| 300mm | 300mm | 300mm | 11.81″ | 11.81″ | 11.81″ |

Features

- Exceptional Material Properties: Fabricated from high-purity fused quartz, offering superior thermal shock resistance, high-temperature stability, and excellent resistance to a wide range of corrosive chemicals.

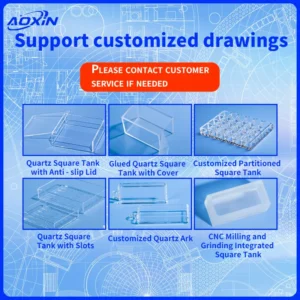

- Unmatched Customization: We excel in creating bespoke containers based on your specific drawings and requirements. Custom features include, but are not limited to:

- Various lid designs (e.g., anti-slip, fitted covers)

- Integrated or attachable handles

- Internal partitions for multi-compartment use

- Precisely machined slots and openings

- Different construction methods (e.g., glued, CNC milled integrated tanks)

- Versatile Applications: Ideal for diverse uses such as chemical processing, semiconductor wafer cleaning, sample storage, etching baths, and more.

- Durability and Precision: Engineered for robust performance and manufactured with high precision to ensure dimensional accuracy and product integrity.

- Full OEM/ODM Support: With our extensive 9000㎡ facility and 15 years of expertise, we provide comprehensive OEM/ODM services from design to production.

- Quality You Can Trust: All products are backed by authoritative certifications (CE, ISO, RoHS, SGS) and rigorous quality control processes.