1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

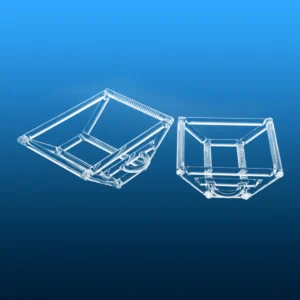

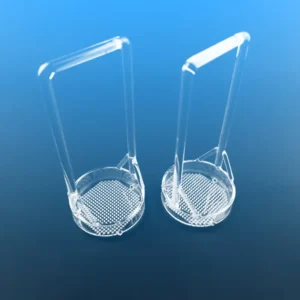

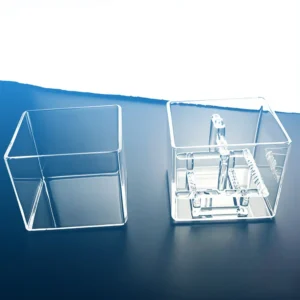

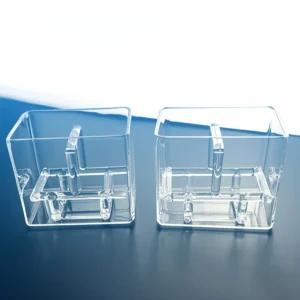

Aoxin Quartz designs and manufactures high-precision Quartz Wafer Cleaning Tank and Rack Systems, essential for critical wet processing steps in semiconductor manufacturing and related high-purity industries. This integrated system comprises a robust outer quartz tank and a custom-fitted inner quartz wafer rack (or carrier) with precision-machined slots. Fabricated from ultra-high purity fused quartz, our tank and rack systems ensure maximum cleanliness and prevent contamination during wafer cleaning, etching, and rinsing processes. The slotted rack allows for uniform exposure of each wafer to processing chemicals and facilitates safe, efficient handling of multiple wafers.

- Product Name : Quartz Wafer Cleaning Tank and Rack System

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

Features

- Ultra-High Purity Environment: Constructed entirely from high-purity fused quartz to eliminate ionic contamination and ensure the integrity of sensitive semiconductor wafers.

- Uniform Wafer Processing: The precision-slotted rack holds wafers separately and securely, ensuring consistent and uniform exposure to cleaning or etching solutions across all wafer surfaces.

- Optimized for Batch Handling: Facilitates efficient processing of multiple wafers simultaneously, improving throughput and reducing handling time.

- Exceptional Chemical Resistance: Quartz is highly resistant to virtually all acids and solvents used in wafer cleaning and etching processes, ensuring long service life and no material degradation.

- High-Temperature Stability: Suitable for heated chemical baths and can withstand high temperatures for subsequent drying or annealing steps if required.

- Safe and Ergonomic Design: The wafer rack typically includes a handle for easy and safe loading, unloading, and transfer between process steps, minimizing wafer damage.

- Precision Manufacturing: Tank and rack dimensions are precisely controlled to ensure proper fit, fluid dynamics, and compatibility with automated or manual handling systems.

- Customizable Solutions: We offer customization of tank dimensions, rack slot size, pitch, capacity, and overall design to meet specific wafer sizes (e.g., 2″, 4″, 6″, 8″, 12″) and process equipment.