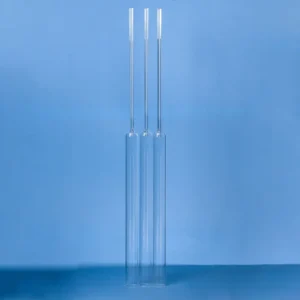

1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

Aoxin Quartz manufactures high-purity, precision-dimensioned Quartz Tubes specifically designed for use as combustion or reduction reactor tubes in elemental analyzers and other high-temperature analytical instrumentation. Crafted from selected fused quartz, these tubes offer exceptional thermal stability (withstanding temperatures well over 1000°C), superior chemical inertness to aggressive reagents and reaction products, and excellent thermal shock resistance. Their consistent dimensions and smooth internal surfaces ensure reliable performance and facilitate proper packing with catalysts and reagents as required by various analytical methods (e.g., CHNS, Dumas, Kjeldahl). Available in various standard and custom sizes to fit a wide range of analytical instruments.

- Product Name : High-Purity Quartz Combustion Tubes

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

Features

- Exceptional High-Temperature Performance: Reliably withstands the extreme temperatures required for complete combustion and reduction reactions.

- Ultra-High Purity: Minimizes sample contamination and background interference, ensuring accurate analytical results.

- Superior Chemical Resistance: Inert to a wide range of aggressive chemicals, catalysts, and reaction byproducts at elevated temperatures.

- Excellent Thermal Shock Stability: Endures rapid heating and cooling cycles common in automated analyzers without cracking or failure.

- Precision Dimensional Control: Manufactured to tight tolerances for consistent fit within analytical instruments and uniform packing of reagents.

- Gas Tightness: Ensures a sealed reaction environment, critical for quantitative analysis.

- Smooth Internal Bore: Facilitates easy and uniform packing of reactor fillings like quartz wool, catalysts, and absorbents.

- Customizable: Can be supplied in various lengths, diameters, and with specific end finishes (e.g., fire-polished, ground) as per instrument requirements.”