1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

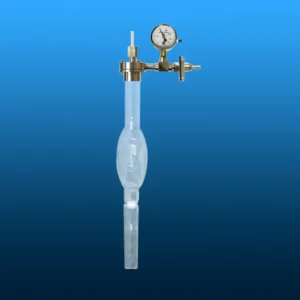

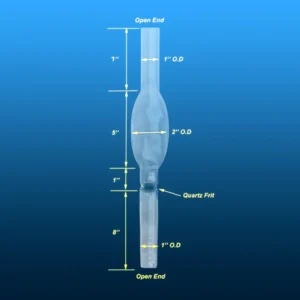

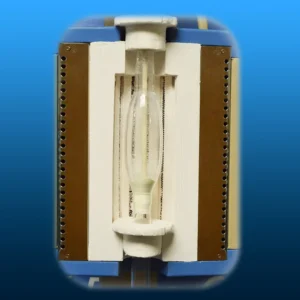

Aoxin Quartz manufactures specialized Quartz Process Tubes featuring an integrally fused fritted disc, designed for high-performance applications in vertical tube furnaces. These tubes are ideal for processes such as fluidized bed reactions, Chemical Vapor Deposition (CVD), and gas-solid catalysis where uniform gas distribution through a particulate bed is critical. Crafted from high-purity fused quartz, our process tubes offer exceptional thermal stability, superior chemical resistance, and precise dimensional control. The integrated quartz frit provides robust support for materials while ensuring even gas flow, and the often enlarged central section enhances mixing and reaction efficiency. These tubes are essential for advanced material synthesis and research at high temperatures under controlled atmospheres.

- Product Name : Quartz Process Tube with Integrated Fritted Disc for Vertical Tube Furnaces

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

Features

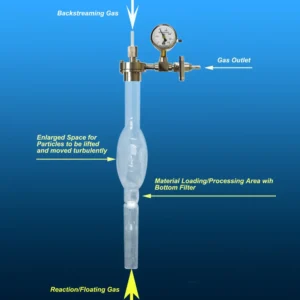

- Uniform Gas Distribution: The integrated quartz fritted disc ensures even dispersion of reactant or fluidizing gases through the material bed, leading to consistent processing.

- Enhanced Reaction Efficiency: The design, often featuring an enlarged reaction zone, promotes better gas-solid contact, turbulence, and fluidization for improved reaction rates and yields.

- High-Purity Processing Environment: Fabricated from high-purity fused quartz to prevent contamination and ensure the integrity of sensitive materials and reactions.

- Exceptional High-Temperature Performance: Designed to withstand the extreme temperatures of vertical tube furnaces without deformation or degradation.

- Superior Chemical & Thermal Shock Resistance: Robust construction and material properties ensure durability against aggressive chemical environments and rapid temperature changes.

- Integrated Material Support: The fritted disc securely holds powders, catalysts, or other particulate materials within the reaction zone.

- Precise Gas Flow Control: Facilitates controlled introduction and exhaust of gases, essential for processes like CVD or controlled atmosphere reactions.

- Customizable Designs: Can be manufactured with various frit porosities, tube diameters, lengths, and configurations to suit specific experimental or production requirements.