1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

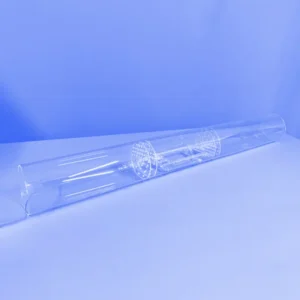

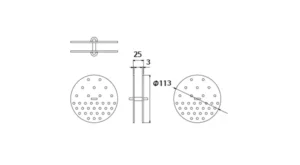

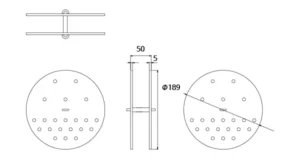

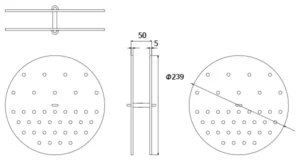

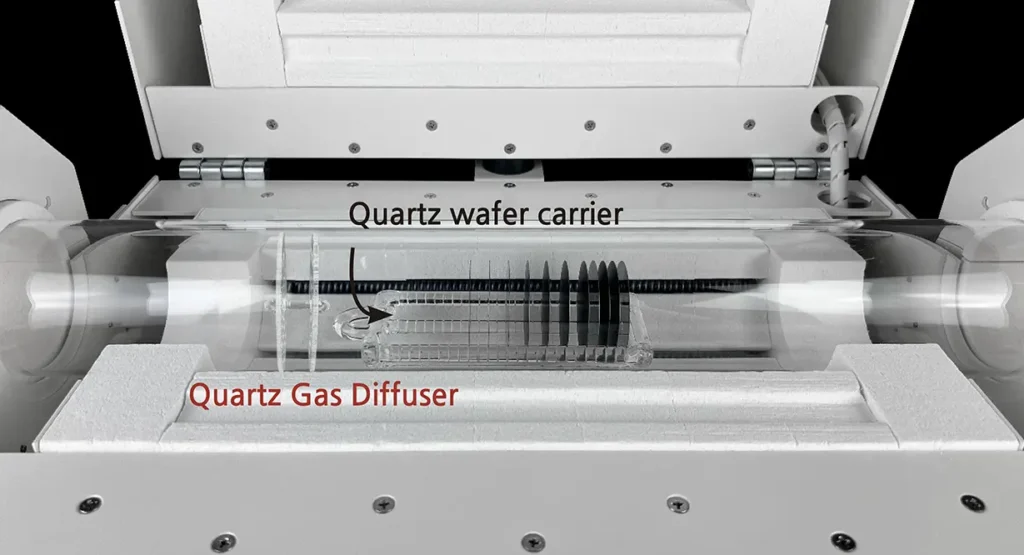

The quartz gas diffuser is specifically designed for quartz tubes used in tubular furnaces. Manufactured from durable and heat-resistant quartz, it ensures long-lasting and reliable performance in laboratories and industries that involve gas-driven thermal processes. It provides excellent control over gas flow in high-temperature furnaces. The diffuser is essential for applications such as Chemical Vapor Deposition (CVD) and heat treatment, ensuring uniform gas distribution, which is vital for obtaining accurate and repeatable research results. Its precise design offers consistent and repeatable outcomes, making it an important tool for various gas-related reactions.

- Product Name : Quartz Tube Furnace Gas Diffuser

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Strain Point : ~1120℃

- Soften point : ~1730℃

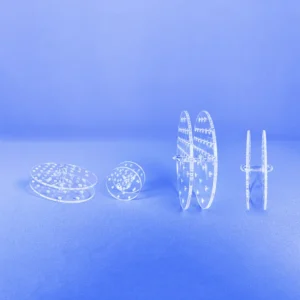

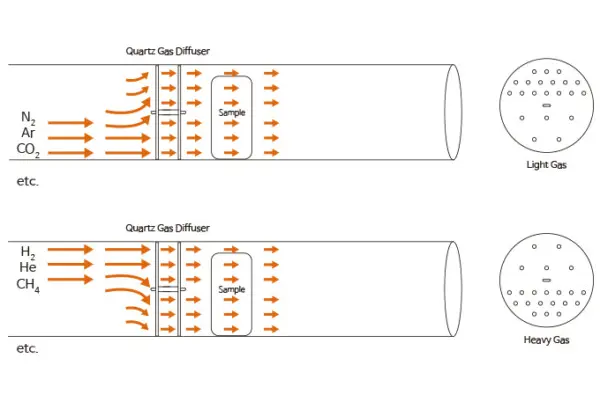

Ensure precise and uniform gas distribution, which is essential for high-precision research. It is highly suitable for Chemical Vapor Deposition (CVD) and heat treatment processes, significantly enhancing material quality and coating uniformity. Made of durable quartz, the diffuser can withstand high temperatures for long-term use. The quartz gas diffuser is highly versatile and can accommodate a variety of gases. For lighter gases such as nitrogen (N₂), argon (Ar), or carbon dioxide (CO₂), the side with multiple holes should be positioned on top. For heavier gases like hydrogen (H₂) or methane (CH₄), the side with many holes should be positioned at the bottom to ensure optimal flow distribution.

The quartz gas diffuser is specifically designed for installation in quartz tubes of tubular furnaces, providing precise gas flow control for furnaces operating at temperatures up to 1200°C. It effectively fills the tube with gas, and by ensuring uniform and consistent gas distribution, the gas diffuser enhances this process, which is crucial for high-precision research.

The diffuser is particularly useful in Chemical Vapor Deposition (CVD) and heat treatment, where a uniform gas environment can significantly affect the quality and consistency of the results. Even minor changes in gas flow can alter the outcomes, making the SH-QDS-80 an indispensable tool for researchers engaged in advanced material synthesis, coatings, and heat treatment.

In some applications, multiple quartz gas diffusers can be placed inside the tube, both before and after the sample boat. This dual setup provides higher uniformity, ensuring a stable gas environment throughout the entire tube. For processes such as CVD and heat treatment, this method can further improve precision and eliminate potential gas flow interruptions.