1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

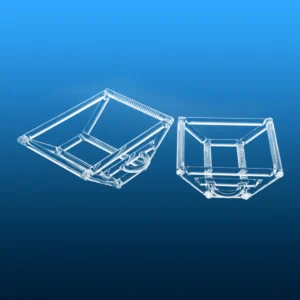

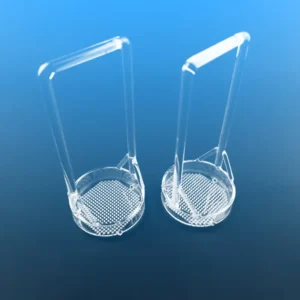

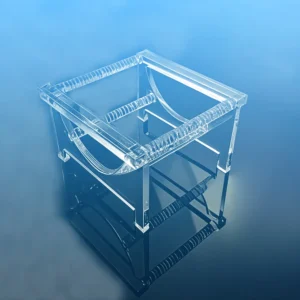

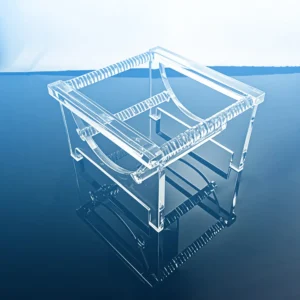

Aoxin Quartz manufactures high-precision Quartz Wafer Cleaning Racks (also known as Quartz Wafer Carriers or Boats), meticulously designed for the safe and efficient handling of semiconductor wafers during critical wet cleaning, etching, and rinsing processes. Crafted from ultra-high purity fused quartz, these racks feature precisely machined slots that securely hold multiple wafers, ensuring uniform exposure to processing chemicals and preventing cross-contamination. Our quartz wafer racks are engineered for maximum chemical resistance, thermal stability, and durability, making them ideal for demanding cleanroom environments and high-purity applications. Custom designs are available to accommodate various wafer sizes and specific processing equipment.

- Product Name : Quartz Wafer Cleaning Rack / Quartz Wafer Carrier

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

Features

- Ultra-High Purity Construction: Made from the highest purity fused quartz to eliminate ionic and particulate contamination, critical for maintaining wafer integrity.

- Precision Wafer Handling: Accurately machined slots provide secure, non-damaging support for wafers, ensuring consistent spacing and orientation for uniform processing.

- Optimized for Chemical Processing: The open-frame design allows for maximum circulation and penetration of cleaning agents, etchants, or rinsing solutions.

- Exceptional Chemical & Thermal Resistance: Withstands aggressive acids, solvents, and high temperatures used in various wet processing and subsequent drying steps.

- Enhanced Durability: Robust quartz construction offers a long service life despite repeated exposure to harsh chemicals and thermal cycling.

- Reduced Particle Generation: The smooth, inert surface of quartz minimizes particle shedding, contributing to a cleaner processing environment.

- Customizable Designs: We can fabricate racks to your specific requirements, including wafer size (e.g., 2″ to 12″), number of slots, slot pitch, overall dimensions, and handling features.

- Improved Process Yields: By ensuring clean, uniform, and damage-free processing, our racks contribute to higher device yields.