1200°C High Temp Resistant

High Transmittance

Acid/Alkali Resistant

Complete Specifications

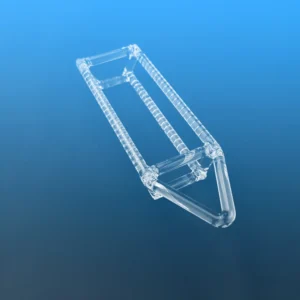

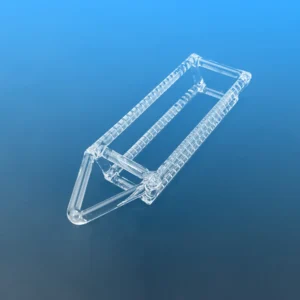

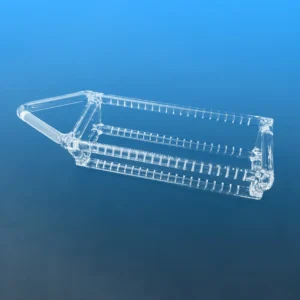

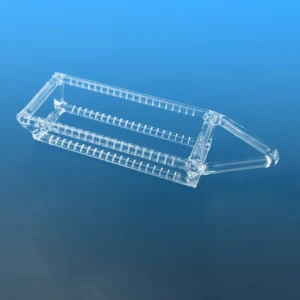

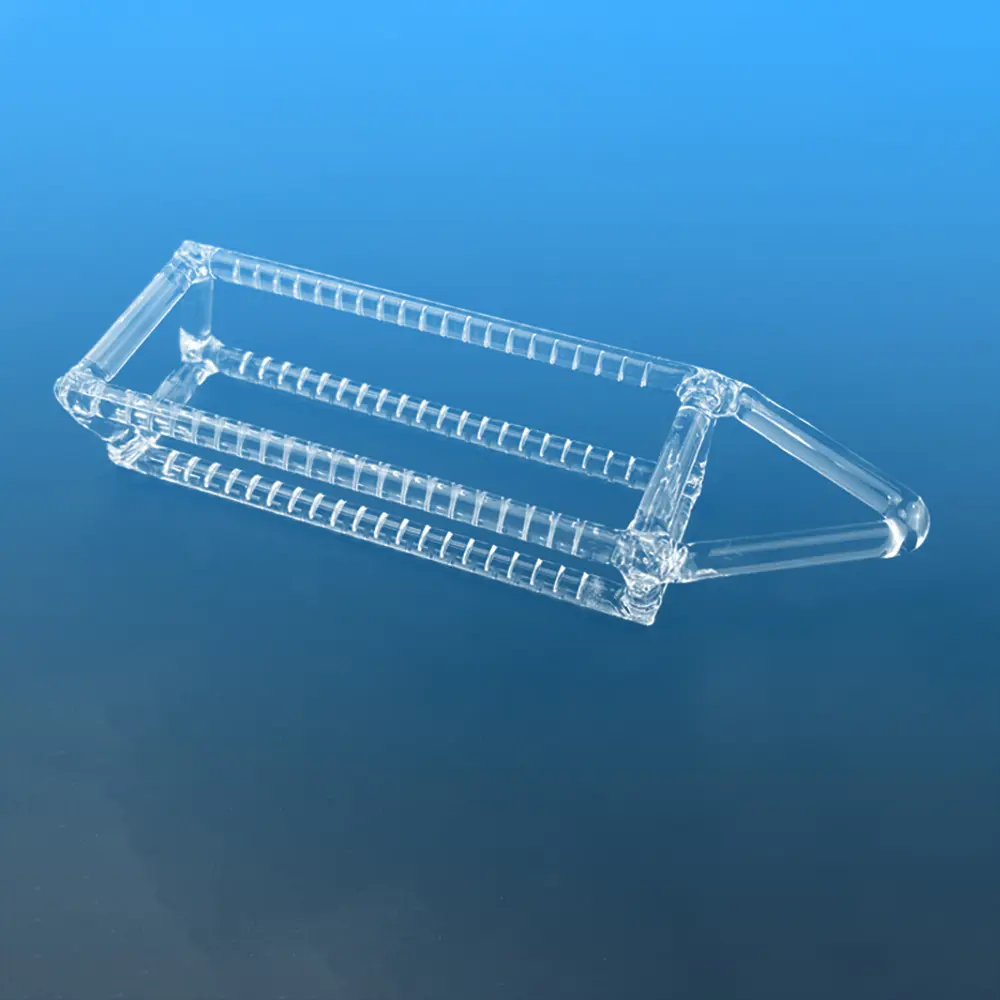

Aoxin Quartz specializes in the manufacture of high-precision Slotted Quartz Boats, engineered for demanding wafer processing and high-temperature annealing applications in the semiconductor and advanced materials industries. These boats are crafted from the highest purity fused quartz, ensuring minimal contamination and exceptional performance at extreme temperatures. Featuring precisely machined slots, our quartz annealing boats provide stable and uniform support for multiple wafers, facilitating consistent thermal treatment, diffusion, or oxidation processes. The robust, open-frame design promotes optimal gas flow and temperature uniformity within the furnace.

- Product Name : Quartz Wafer Carrier with Perforated Base and Handle

- Material : 99.99 % Purity Quartz

- Work Temperature :~1200℃

- Soften point : ~1730℃

- Hardness : 5.5 – 6.5 Mohs’ Scale 570 KHN 100

- Tensile Strength : 4.8×107 Pa (N/mm2) (7000 psi)

- Compression Strength : >1.1×109 Pa (160,000 psi)

Features

- Ultra-High Purity for Contamination Control: Fabricated from select high-purity fused quartz to prevent outgassing and diffusion of impurities into wafers during high-temperature annealing and processing.

- Exceptional High-Temperature Stability: Designed to withstand extreme temperatures (often >1000°C) encountered in furnace annealing, diffusion, and oxidation processes without significant sagging or devitrification.

- Superior Thermal Shock Resistance: Capable of enduring rapid temperature changes during loading and unloading from hot furnace zones, minimizing the risk of cracking.

- Precision Wafer Slotting: Accurately machined slots ensure wafers are held securely, with consistent spacing for uniform heat treatment and gas exposure across the entire batch.

- Optimized for Uniform Processing: The open design allows for excellent gas flow dynamics and temperature uniformity, critical for consistent process results.

- Chemical Inertness: Highly resistant to process gases and cleaning chemicals used in semiconductor fabrication.

- Durability and Long Service Life: Robust construction for reliable performance over many thermal cycles.

- Custom Designs: Available in various lengths, slot pitches, slot depths, and end-handler configurations to match specific wafer sizes and furnace automation requirements.